Views and Life Cycles

A Product Structure View is mostly one of several presentations of the Product Structure or part of it on a computer screen or an output on paper, often called Bill of Material. As described below, it is possible to have several Views or presentations of the Product Structure. The possibilities to-day is quite different from te days when the Bill of Material was written in ink on paper.

A Product Structure View is mostly one of several presentations of the Product Structure or part of it on a computer screen or an output on paper, often called Bill of Material. As described below, it is possible to have several Views or presentations of the Product Structure. The possibilities to-day is quite different from te days when the Bill of Material was written in ink on paper.

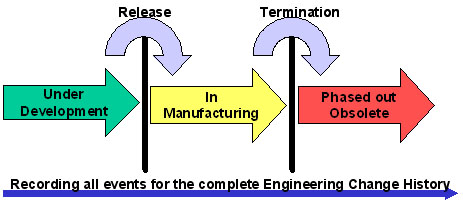

By Life Cycle in this context, I assume the Life Cycle of the Nominal Product in the Products Structure in the databases of the PDM application. The Life Cycle starts with the definition of a Product Development Project or when a an Engineering Change has been decided to be developed and ends when the Nominal Product is phased out of Production and has become History. Please notice that the complete History of the Life Cycle any Nominal Product is recorded and kept indefinitely.

The PDM applications shall support:

Product Engineering and Manufacturing Engineering which will call for several views and different ”slicing” of the Products, such as:

- The entire Product but subdivided by Function Group

- By an entire System such as Electrical System, Hydraulic system, Pneumatic System etc. subdivided within each System.

- The entire Product but subdivided by the Plants where different Components and Assemblies are manufactured.

- The Entire Product or a View shown within a Time Interval where Parts that will be ”current” depending of the effectivity in different ECNs will be shown.

- Combinations of these

- In word and figures or geometrical.

Product Development Projects from the start which means that there must be a capability to differentiate between what is

- Under work and not yet released for manufacturing

- Released and in current production

- Phased out of production and obsolete – but captured as history.

In other words: The recording of the entire Life Cycle Management for the Nominal Product from ”before the conception until the grave – or is recycled”!

- ERNs (or ECNs) from the creation of such, through approval and release until they are implemented and the effectivity dates and serial numbers for this has been captured.

- Parts Planning will need to sort the Prodct Structure Parts according to their exploded view drawings Principal

- Principal Variant Specification or ”PV-Spec”

The PV-Spec is a BoM with an information structure that will enable the specification of the Nominal Product

- as it will be,is being and has been manufactured, independent of which Plant it is manufactured at and independent of where in the life cycle the Nominal Product is.

- The user shall be able to retrieve a Product Structure Information with the latest released Engineering Changes regardless of whether these have been effected in manufacturing or not: ”Engineering Status”

- All released and effected Engineering Changes some Engineering Changes effected specified by a Date in the past or in the future: ”Spec Date Status”

- as the Product is being manufactured at the moment of retrieval: ”Manufacturing Status”.